Blue Projects perspective on 3D Laser Scanning

The standard of our work at Blue Projects is to maximize the use of available, modern tools and procedures to improve the design and coordination process.

With the passing of time on existing facilities, after 15-40 years of operation, the availability or condition of documentation may not be sufficient for the next project.

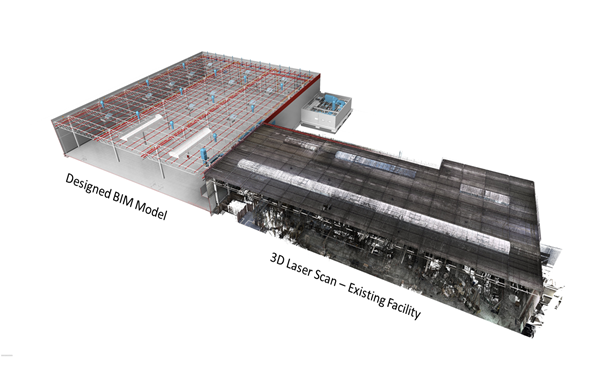

In such cases, 3D Terrestrial Laser Scanning and BIM technologies can be useful. Terrestrial Laser Scanning (TLS) is a non-invasive measurement technique in which laser technology is used to measure the distance between a given point (for example, a wall) and a laser scanner. The result of these measurements is a set of points in xyz space, which form a virtual image of the object being measured, called a 3D point cloud.

The use of the 3D scanner image as reference material for spatial design and analysis significantly improves the coordination and efficiency of the design process. Advantages of this measurement method include short time and high accuracy. In addition to being much faster and more accurate than conventional building measurement techniques, it also allows textures from photographs taken during the survey to be superimposed on the resulting 3D image of the object. In this way, it is possible to obtain a colour 3D scan and images in the form of 360 panoramas.

The 3D colour scan is particularly useful for the visual identification of installations (utilities), which are usually closely arranged in industrial facilities. In addition, the most up-to-date spatial data becomes available, so we know what needs to be dismantled and what modifications need to be made to the existing systems or process lines.

This technology is an excellent tool for carrying out analysis in terms of space, volume or relocation of equipment or replacement of installations.

Scanning technology gives us access to dimensions, images and a continuous overview of the object under development without the need to travel to the construction site to take measurements or check the correctness of the designed assumptions.

It is important to remember that the use of scanning does not eliminate the need to carry out technical assessments of existing facilities or to have design teams visit the site under development.

The results obtained from the terrestrial scanner can be combined with the point cloud resulting from the application of the photogrammetry. Photogrammetry in a simplified definition is the reproduction of three-dimensional shapes using photographed pictures. We can use this technique for large areas of roofs. Using a drone, we can take a flight and do photographs, outside the building, without the additional works at height required for measurements on the roof.

The data in the form of a point cloud can be directly used by BIM software.

As a result, working in a 3D environment, we can see the full spectrum of issues and challenges associated with design work on an existing building.

By modelling in 3D, we are able to carry out analyses relating to the routing of installations without affecting the existing structure.

Usually, laser scanning data cause very large files, which can increase storage and processing time and resources. In addition, high-performance hardware is required to process laser data and an experienced technical team is needed to process the data correctly. Therefore, obtaining, processing, and managing this data is a challenging process.

However, laser scanning data may not be sufficient to determine exactly where a building’s load-bearing elements are. Particularly, if the as-built information for a building is unavailable and there are invisible elements covered with plaster, beams inside suspended ceilings, in between interior and exterior claddings or support elements in walls. For such cases, field & lab tests and field measurements will need to be conducted to fully understand the structure.

- use GNSS to install site control outside of the buildings so that all scan data and modelling will be related to the national level datum (OS datum). We can provide the data to OS grid or an agreed site/plant grid. This is to be discussed and agreed in advance.

- deploy a Leica RTC360 scanner, Faro Focus or equivalent and perform point cloud capture. The completeness of the survey is dependent on safe and efficient access and the ability of the scanner to ‘see’ the structures.

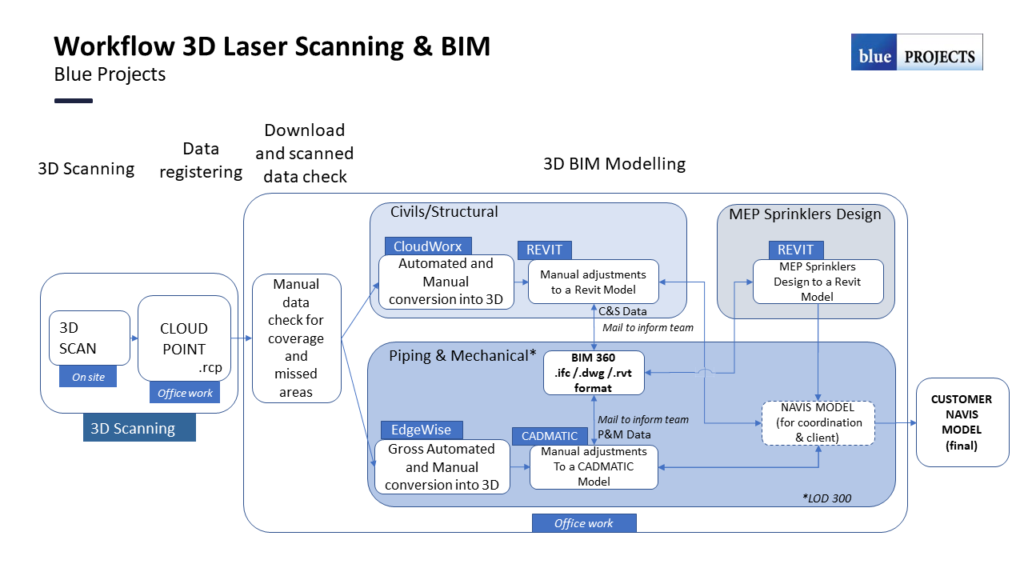

- Post processing includes scan registration, point cloud decimation and integration into Database System. Scans will be registered together in Leica Cyclone software using a combination of cloud registration and targets.

- The BIM model will be generated from the laser point cloud data according to the Level of Development (LOD) Specification for Building Information Models (BIMs), which is a guideline / reference for what to include and to what accuracy for each level of detail.

- If required, structural/architectural drawings (plans, elevations, and sections) can be created from the 3D Model.

- Model will be generated per true asbuilt conditions. Note that model elements will likely not be perfectly parallel / perpendicular, but rather will reflect actual field conditions.

Additional features & options

- 360 degree & 2D Photographs

- Aerial Drone Mapping

This would serve beneficial during all phases of the project and can be used to bid specific renovation work. Typically, the assessment team will remotely walk the facility to build and prioritize their agenda for when they find themselves onsite.

In conclusion, laser scanning data is an important tool in the processes of creating a structural element model, design, and analysis. It helps us determine details such as the geometry, size, material, and load-bearing elements of the structure, as well as identify problems and detect damage.

Based on our experience at Blue Projects, we can conclude that in construction, especially industrial construction, the use of 3D scanning gives much better results and improves the efficiency of design work than traditional measuring techniques.

This allows us to accurately plan and effectively communicate to the client any design issues related to rebuilt or extended facilities.